Karakaş, Mustafa Serdar

Loading...

Profile URL

Name Variants

Karakas, Mustafa Serdar

Job Title

Doç. Dr.

Email Address

Main Affiliation

06.07. Malzeme Bilimi ve Mühendisliği

Malzeme Bilimi ve Mühendisliği

06. Mühendislik Fakültesi

01. Çankaya Üniversitesi

Malzeme Bilimi ve Mühendisliği

06. Mühendislik Fakültesi

01. Çankaya Üniversitesi

Status

Former Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

SDG data is not available

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

4

Articles

4

Views / Downloads

16/0

Supervised MSc Theses

0

Supervised PhD Theses

0

WoS Citation Count

58

Scopus Citation Count

60

WoS h-index

2

Scopus h-index

2

Patents

0

Projects

0

WoS Citations per Publication

14.50

Scopus Citations per Publication

15.00

Open Access Source

2

Supervised Theses

0

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Nuclear Technology and Radiation Protection | 1 |

| Surface and Coatings Technology | 1 |

| Zeitschrift für Naturforschung A | 1 |

Current Page: 1 / 1

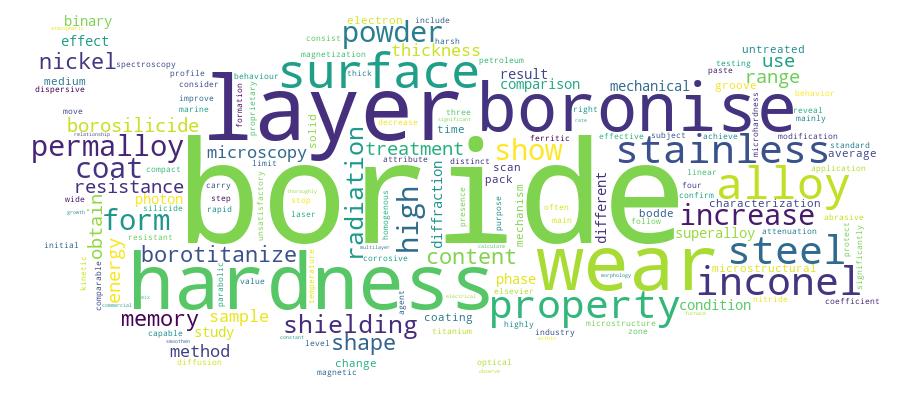

Competency Cloud