Özdoğan, Cem

Loading...

Profile URL

Name Variants

Özdoǧan, C.

Özdogan, C

Özdoğan, C.

Ozdogan, C.

Özdoğan, Cem

ÄozdoGan, C.

Özdoğan, Cem

Oezdogan, C.

Ozdogan, Cem

Ozdogan, C

Özdoğan, Cem

Özdoğan, Cem

Özdogan, C

Özdoğan, C.

Ozdogan, C.

Özdoğan, Cem

ÄozdoGan, C.

Özdoğan, Cem

Oezdogan, C.

Ozdogan, Cem

Ozdogan, C

Özdoğan, Cem

Özdoğan, Cem

Job Title

Doç. Dr.

Email Address

Main Affiliation

09.01. Ortak Dersler Bölümü

09. Rektörlük

01. Çankaya Üniversitesi

09.01. Ortak Dersler Bölümü

Ortak Dersler Bölümü

09. Rektörlük

01. Çankaya Üniversitesi

09. Rektörlük

01. Çankaya Üniversitesi

09.01. Ortak Dersler Bölümü

Ortak Dersler Bölümü

09. Rektörlük

01. Çankaya Üniversitesi

Status

Former Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

13

CLIMATE ACTION

0

Research Products

8

DECENT WORK AND ECONOMIC GROWTH

0

Research Products

3

GOOD HEALTH AND WELL-BEING

0

Research Products

15

LIFE ON LAND

0

Research Products

17

PARTNERSHIPS FOR THE GOALS

0

Research Products

14

LIFE BELOW WATER

0

Research Products

4

QUALITY EDUCATION

0

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

0

Research Products

6

CLEAN WATER AND SANITATION

0

Research Products

10

REDUCED INEQUALITIES

0

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

1

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

0

Research Products

2

ZERO HUNGER

0

Research Products

1

NO POVERTY

0

Research Products

7

AFFORDABLE AND CLEAN ENERGY

2

Research Products

5

GENDER EQUALITY

0

Research Products

16

PEACE, JUSTICE AND STRONG INSTITUTIONS

0

Research Products

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

31

Articles

26

Views / Downloads

1577/46

Supervised MSc Theses

0

Supervised PhD Theses

0

WoS Citation Count

797

Scopus Citation Count

701

WoS h-index

11

Scopus h-index

12

Patents

0

Projects

0

WoS Citations per Publication

25.71

Scopus Citations per Publication

22.61

Open Access Source

7

Supervised Theses

0

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Physical Review B | 4 |

| Nanotechnology | 2 |

| Physical Review B - Condensed Matter and Materials Physics | 2 |

| The Journal of Physical Chemistry C | 2 |

| Communications in Nonlinear Science and Numerical Simulation | 1 |

Current Page: 1 / 5

Scopus Quartile Distribution

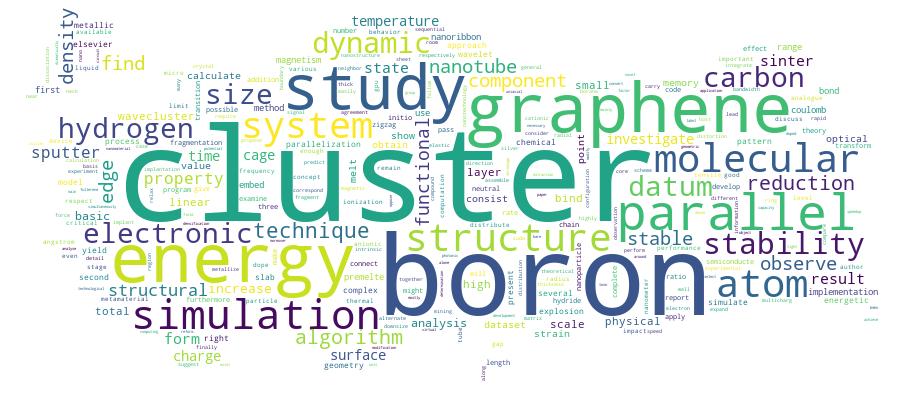

Competency Cloud

31 results

Scholarly Output Search Results

Now showing 1 - 10 of 31

Article Citation - WoS: 31Citation - Scopus: 30Ionization Energies, Coulomb Explosion, Fragmentation, Geometric, and Electronic Structures of Multicharged Boron Clusters Bn (n=2-13)(Amer Physical Soc, 2011) Tas, Murat; Ozdogan, Cem; Boustani, Ihsan; Akman, NurtenBased on the ab initio quantum chemical methods, we have determined fragmentation channels, ionization energies, and the Coulomb explosion of multicharged boron clusters B-n (n = 2-13), where n is the cluster size. The electron-deficient boron clusters sustain more stability and hardly fragment when they are negatively charged. Stability of boron clusters decreases with increasing ionization. Only by the first ionization the odd-size clusters are more stable than the even-size clusters. Further ionizations cause the repulsive Coulomb force between the constituent atoms to get stronger, and lead first to metastable states, then to the Coulomb explosion of clusters. None of the cationic boron clusters studied remain stable after six times ionization. The critical charge for metastability is estimated as Q(m) <= n/2 for even-size clusters, and Q(m) <= 1/2 (n - 1) for odd-size clusters. In addition, the critical charge for the Coulomb explosion is found to be Q(c) = n/2 + 1 for even-size clusters, and Q(c) = 1/2(n + 1) for odd-size clusters. Relative stability of clusters with respect to their nearest neighbors is determined from the analysis of their second energy difference data. Several dissociation channels of B-n(+) and B-13(Q) isomers with the lowest fragmentation energies are presented. All of the vibrational frequencies are found positive indicating that no transition state is possible for the clusters studied. Reliability of our data is verified with a good agreement with experimental results.Article Citation - WoS: 22Citation - Scopus: 21Functionalizing Graphene by Embedded Boron Clusters(Iop Publishing Ltd, 2008) Ozdogan, Cem; Kunstmann, Jens; Fehske, Holger; Quandt, AlexanderWe present a model system that might serve as a blueprint for the controlled layout of graphene based nanodevices. The systems consists of chains of B-7 clusters implanted in a graphene matrix, where the boron clusters are not directly connected. We show that the graphene matrix easily accepts these alternating B-7-C-6 chains and that the implanted boron components may dramatically modify the electronic properties of graphene based nanomaterials. This suggests a functionalization of graphene nanomaterials, where the semiconducting properties might be supplemented by parts of the graphene matrix itself, but the basic wiring will be provided by alternating chains of implanted boron clusters that connect these areas.Article Citation - WoS: 32Density Functional Study of Physical and Chemical Properties of Nano Size Boron Clusters: Bn (n=13-20)(Chinese Physical Soc, 2009) Ozdogan, Cem; Guvenc, Ziya B.; Atis, MuratBoron is an element that has ability to build strong and highly directional bonds with boron itself. As a result, boron atoms form diverse structural motifs, ultimately can yield distinct nano structures, such as planar, quasi-planar, convex, cage, open-cage, tubular, spherical., ring, dome-like, shell, capsule, and so on, i.e., it can take almost any shape. Therefore, a deep understanding of the physical and chemical properties becomes important in boron cluster chemistry. Electronic and geometric structures, total and binding energies, harmonic frequencies, point symmetries, charge distributions, dipole moments, chemical bondings and the highest occupied molecular orbital-lowest unoccupied molecular orbital energy gaps of neutral B-n (n=13-20) clusters have been investigated by, density functional theory (DFT), B3LYP with 6-311++G(d,p) basis set. Furthermore, the first and the second energy differences are used to obtain the most stable sizes. We have observed that almost all physical properties are size dependent, and double-ring tubular form of B-20 has the highest binding energy per atom. The icosahedral structure with an inside atom is found as impossible as a stable structure for the size thirteen. This structure transforms to an open-cage form. The structural transition from two-dimensional to three-dimensional is found at the size of 20 and consistent with the literature. The calculated charges by the Mulliken analysis show that there is a symmetry pattern with respect to the x-z and y-z planes for the charge distributions. The unusual planar stability of the boron clusters may be explained by the delocalized pi and sigma bonding characteristic together with the existence of the multicentered bonding. The results have been compared to available studies in the literature.Article Hydrogen hosting of nanoscale boron cluster(Editura Academiei Romane, 2008) Böyükata, Mustafa; Özdoğan, C.; Güvenç, Ziya B.In this paper the Density Functional Results of hydrogen bonded boron micro clusters with B3LYP/6-311++G(d,p) level of computations will be presented. Energetics and structural stability with their possible stable geometries of various selected micro complexes of B(m)H(n) (for m and n <= 11 )boron hydrides have been analysed, and their binding energies with HOMO-LUMO energy gaps have been determined. Mainly, erects of the number of hydrogen atoms on the structures of the boranes are assessed. Moreover, for the cage configurations their distortions have been investigated for the neutral, anionic and cationic cases. It has been observed that there have been two opposing factors for the cage configurations. One of which is the "peeling" of the cage structures by the hydrogen atoms, and the other one is reforming a smaller cage form simultaneously with there remaining boron atoms inside. This is observed mostly for the odd values of m. From our studies it has been also observed that with the bare boronclusters alone, it is difficult to increase the capacity of the hydrogen storage. Therefore, further studies are necessary with the boron complexesArticle Citation - WoS: 107Citation - Scopus: 111Determination of Complete Melting and Surface Premelting Points of Silver Nanoparticles by Molecular Dynamics Simulation(Amer Chemical Soc, 2013) Yavuz, M.; Zhou, Y.; Alarifi, H. A.; Atis, M.; Ozdogan, C.; Hu, A.A molecular dynamics simulation based on the embedded-atom method was conducted at different sizes of single-crystal Ag nanoparticles (NPs) with diameters of 4 to 20 nm to find complete melting and surface premelting points. Unlike the previous theoretical models, our model can predict both complete melting and surface premelting points for a wider size range of NPs. Programmed heating at an equal rate was applied to all sizes of NPs. Melting kinetics showed three different trends that are, respectively, associated with NPs in the size ranges of 4 to 7 rim, 8 to 10 nm, and 12 to 20 nm. NPs in the first range melted at a single temperature without passing through a surface premelting stage. Melting of the second range started by forming a quasi-liquid layer that expanded to the core, followed by the formation of a liquid layer of 1.8 nm thickness that also subsequently expanded to the core with increasing temperature and completed the melting process. For particles in the third range, the 1.8 nm liquid layer was formed once the thickness of the quasi-liquid layer reached S rim. The liquid layer expanded to the core and formed thicker stable liquid layers as the temperature increased toward the complete melting point. The ratio of the quasi-liquid layer thickness to the NP radius showed a linear relationship with temperature.Article Citation - WoS: 160The Unusually Stable B100 Fullerene, Structural Transitions in Boron Nanostructures, and a Comparative Study of Α- and Γ-Boron and Sheets(Amer Chemical Soc, 2010) Mukhopadhyay, S.; Hayami, W.; Guvenc, Z. B.; Pandey, R.; Boustani, I.; Ozdogan, C.Solid alpha-B-12 rhombohedral and gamma-B-28 orthorhombic boron as well as boron nanostructures in the form of spheres, sheets, and multirings beside a ring consisting of icosahedral B-12 units were investigated using ab initio quantum chemical and density functional methods. The structure of the 131(x) fullerene exhibits unusual stability among all noninteracting free-standing Clusters, and is more stable than the 13120 cluster fragment of the gamma-B-28 solid, recently predicted and observed by Oganov et al. (Nature 2009, 457, 863). In addition, we compared the stability of the multirings and reported the structural transition from double-ring to triple-ring systems. This structural transition Occurs between B-52 and B-54 Clusters. We confirm that the noninteracting free-standing triangular buckled-sheet is more stable than the gamma-sheet, assembled in this work, and than the a-sheet, proposed by Tang and Ismail-Beigi (Phys. Rev. Lett. 2007, 99, 115501). In contrast, however, when these sheets are considered as infinite periodic systems, then the a-sheet remains the most stable one.Article Structural stability and energetics of single-walled carbon nanotubes under uniaxial strain(2003) Dereli, G.; Özdoğan, CemA (10x10) single-walled carbon nanotube consisting of 400 atoms with 20 layers is simulated under tensile loading using our developed O(N) parallel tight-binding molecular-dynamics algorithms. It is observed that the simulated carbon nanotube is able to carry the strain up to 122% of the relaxed tube length in elongation and up to 93% for compression. Young's modulus, tensile strength, and the Poisson ratio are calculated and the values found are 0.311 TPa, 4.92 GPa, and 0.287, respectively. The stress-strain curve is obtained. The elastic limit is observed at a strain rate of 0.09 while the breaking point is at 0.23. The frequency of vibration for the pristine (10x10) carbon nanotube in the radial direction is 4.71x10(3) GHz and it is sensitive to the strain rate.Article Citation - Scopus: 10O(N) Algorithms in Tight-Binding Molecular-Dynamics Simulations of the Electronic Structure of Carbon Nanotubes(2003) Dereli, G.; Özdoǧan, C.The O(N) and parallelization techniques have been successfully applied in tight-binding moleculardynamics simulations of single-walled carbon nanotubes (SWNT's) of various chiralities. The accuracy of the O(N) description is found to be enhanced by the use of basis functions of neighboring atoms (buffer). The importance of buffer size in evaluating the simulation time, total energy, and force values together with electronic temperature has been shown. Finally, through the local density of state results, the metallic and semiconducting behavior of (10 X 10) armchair and (17 X 0) zigzag SWNT's, respectively, has been demonstrated.Publication About nanometer sized analogues of basic electronic and optical components(IEEE, 2008) Quandt, Alexander; Özdoğan, Cem; Ferrari, Maurizio; Speranza, GiorgioWe discuss a downsizing of optical components into the nanometer range. It presupposes the substitution of photons by ballistic electrons, but it also requires a simple and robust concept to assemble the analogues of basic electronic and optical components on such a tiny length scale. Here, one of the most promising candidate schemes employs graphene as a basic nanosubstrate. We elucidate the suggested behaviour of graphene as an electronic metamaterial [1], and show that other desired electronic or optical functionalities may be obtained through a patterning with sub-nanometer sized boron clusters [2].Article Synthesis, Molecular Structure and Dft Study of 2-(n Benzoate(Springer/plenum Publishers, 2011) Kazak, Canan; Ozdogan, Cem; Guvenc, Ziya B.; Buyukgungor, Orhan; Arslan, Figen; Odabasoglu, Mustafa; Yuksektepe, CigdemThe biologically important 2-amino-3-hydroxypyridine reacts with benzoyl chloride to give 2-(N-benzoylbenzamido)pyridine-3-yl benzoate. This synthesized compound has been studied by elemental analysis, X-ray crystallography and also theoretically by density functional theory (DFT) framework with B3LYP/6-311++G(d, p) level of theory. The molecules of this compound crystallize in the orthorhombic space group of P2(1)2(1)2(1) and the crystal packing involves both hydrogen-bonding and C-Ha <-pi interaction. The vibrational normal modes of the molecular structure are investigated by ab initio method for both infrared intensities (IR) and for Raman activities. Furthermore, the corresponding assignments are discussed. Hydrogen and carbon atoms of the benzene rings are found to be highly active. Also, experimentally obtained IR spectrum is presented and compared with the available theoretical data. Experimentally and theoretically obtained IR spectrum are in good agreement.