Çoğun, Can

Loading...

Profile URL

Name Variants

Cogun, Can

Çoğun, C.

Çoğun, Can

Çoğun, Can

Çoğun, Can

Cogun, C.

Çoǧun, C.

Çoǧun, Can

Çoğun, Can

Çoğun, C.

Çoğun, Can

Çoğun, Can

Çoğun, Can

Cogun, C.

Çoǧun, C.

Çoǧun, Can

Çoğun, Can

Job Title

Prof. Dr.

Email Address

cogun@cankaya.edu.tr

Main Affiliation

06.08. Mekatronik Mühendisliği

06. Mühendislik Fakültesi

01. Çankaya Üniversitesi

06.08. Mekatronik Mühendisliği

Mekatronik Mühendisliği

06. Mühendislik Fakültesi

01. Çankaya Üniversitesi

06. Mühendislik Fakültesi

01. Çankaya Üniversitesi

06.08. Mekatronik Mühendisliği

Mekatronik Mühendisliği

06. Mühendislik Fakültesi

01. Çankaya Üniversitesi

Status

Current Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Files

Sustainable Development Goals

13

CLIMATE ACTION

0

Research Products

8

DECENT WORK AND ECONOMIC GROWTH

0

Research Products

3

GOOD HEALTH AND WELL-BEING

0

Research Products

15

LIFE ON LAND

0

Research Products

17

PARTNERSHIPS FOR THE GOALS

0

Research Products

14

LIFE BELOW WATER

0

Research Products

4

QUALITY EDUCATION

0

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

0

Research Products

6

CLEAN WATER AND SANITATION

0

Research Products

10

REDUCED INEQUALITIES

0

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

19

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

0

Research Products

2

ZERO HUNGER

0

Research Products

1

NO POVERTY

0

Research Products

7

AFFORDABLE AND CLEAN ENERGY

0

Research Products

5

GENDER EQUALITY

0

Research Products

16

PEACE, JUSTICE AND STRONG INSTITUTIONS

0

Research Products

This researcher does not have a Scopus ID.

This researcher does not have a WoS ID.

Scholarly Output

31

Articles

25

Views / Downloads

1030/68

Supervised MSc Theses

0

Supervised PhD Theses

0

WoS Citation Count

245

Scopus Citation Count

277

WoS h-index

9

Scopus h-index

9

Patents

0

Projects

0

WoS Citations per Publication

7.90

Scopus Citations per Publication

8.94

Open Access Source

13

Supervised Theses

0

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Gazi Üniversitesi Mühendislik Mimarlık Fakültesi Dergisi | 3 |

| Machining Science and Technology | 2 |

| 38th Annual Conference of the European-Prosthodontic-Association -- SEP, 2014 -- Istanbul, TURKEY | 1 |

| 7th. International Powder Metallurgy Conference | 1 |

| Arabian Journal for Science and Engineering | 1 |

Current Page: 1 / 6

Scopus Quartile Distribution

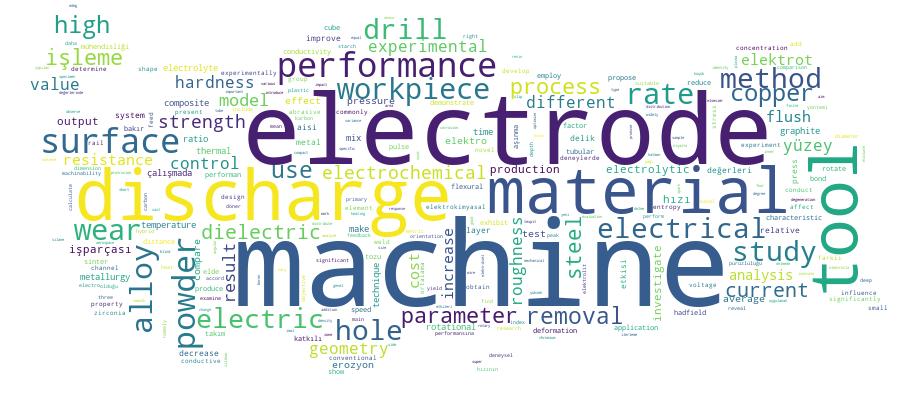

Competency Cloud

31 results

Scholarly Output Search Results

Now showing 1 - 10 of 31

Article Döner Tüp Takım Kullanarak Elektrokimyasal Delme Yönteminin Deneysel İncelenmesi ve Geliştirilmesi(2013) Çoğun, Can; Özerkan, H. BekirBu çalışmada, alışılmamış imal usullerinden elektrokimyasal işleme yöntemi esaslı yeni bir hibrit elektrokimyasal delik delme (EKD) yöntemi geliştirilmiştir. Geliştirilen yöntemde takımın dönme hareketi yanında içinden elektrolit püskürtmesi de uygulanmaktadır. Yöntemin denemelerinin gerçekleştirilebilmesi için küçük boyutlarda bir prototip EKD tezgâhı tasarlanmış ve üretilmiştir. Yeni sistemin önemli özelliklerinden biri işlemede takım ilerleme hızının akım geri besleme kontrolü ile ayarlanmasıdır. Prototip tezgâhta, talaşlı imal usulleriyle gerinme pekleşmesinden dolayı işlenmesi çok güç olan Hadfield (mangan) çeliği ve işlenebilirliği iyi olan AISI 1040 çeliği aynı işleme koşullarında delinmiş ve sonuçlar karşılaştırılmıştır. Her iki çelikle yapılan deneylerde işleme geriliminin, takım dönüş hızının, elektrolit konsantrasyonunun ve püskürtme basıncının artışıyla işparçası işleme hızı değerleri artmıştır. Ortalama yanal açıklık değerleri takım dönüş hızının artışı ile artmıştır. AISI 1040 çeliğine açılan deliklerin Hadfield çeliğine göre daha düzgün olduğu görülmüştür. Deneysel sonuçlar önerilen yeni hibrit EKD yöntemi ile işlenmesi güç malzemelere derin ve küçük çaplı deliklerin kolaylıkla açılabileceğini göstermiştir.Article Citation - WoS: 7Citation - Scopus: 7Thermo-Fluid Multi-Physics Modeling and Experimental Verification of Volumetric Workpiece Material Removal by a Discharge Pulse in Electric Discharge Machining Process(Iop Publishing Ltd, 2020) Cogun, Can; Uslan, Ibrahim; Erbas, Murat; Erdem, OguzThe volume of material removed from the workpiece by a pulse (V-v) in the electric discharge machining was quantitatively determined using a multi-physics simulation model in ANSYS CFX software. Electrical heating is used in the model to simulate the plasma channel formation by defining the boundary and time-controlled current density initial conditions. Time-dependent physical properties at plasma temperature were used to reflect the actual processing environment. The heat was transferred from the plasma channel to the workpiece by electrical heating from the electrode, and V(v)was calculated by means of the amount of heat transfer. The calculated V(v)values for AISI4140, Ti6Al4V and Inconel 718 workpieces were lower than the experimental results and the difference was observed to change between 38.3% and 46.9%.Article Citation - WoS: 10Citation - Scopus: 9The Effect of Powder Mixed and Heated Dielectric on Drilling Performance of Electric Discharge Machining (Edm)(Gazi Univ, Fac Engineering Architecture, 2016) Cogun, Can; Urtekin, Levent; Ozerkan, H. Bekir; Uslan, Ibrahim; Erdem, OguzIn this study, heated silicon oil with added carbon and starch powders was used as dielectric liquid, instead of common hydro-carbon based dielectrics, to obtain better hole surface quality with rotating brass tube electrode in electric discharge machining (EDM). The electro-rheometer tests were conducted to find out the suitable temperature and powder concentration values of the electro-rheological (ER) dielectric under the electric field. Higher workpiece material removal rates (MRR) was obtained in carbon powder added dielectrics than the starch powder added ones for rotating and non-rotating electrodes. The optical microscope observations of the machined hole surfaces indicated that the carbon powder added dielectrics reduced the diameter and depth of the discharge craters, thereby resulting in uniformly distributed and round top peaked surface topography. The starch powder addition to the carbon mixed dielectric further improved the surface quality for both rotating and non-rotating electrodes cases at 30 degrees C and 75 degrees C dielectric temperatures.Article Citation - WoS: 30Citation - Scopus: 34Performance and Surface Alloying Characteristics of Cu-Cr and Cu-Mo Powder Metal Tool Electrodes in Electrical Discharge Machining(Taylor & Francis inc, 2016) Uslan, Ibrahim; Usta, Yusuf; Cogun, Can; Gulcan, OrhanThe main objective of this study is to investigate the effect of Cu-Cr and Cu-Mo powder metal (PM) tool electrodes on electrical discharge machining (EDM) performance outputs. The EDM performance measures used in the study are material removal rate (MRR), tool electrode wear rate (EWR), average workpiece surface roughness (R-a), machined workpiece surface hardness, abrasive wear resistance, corrosion resistance, and workpiece alloyed layer depth and composition. The EDM performance of Cu-Cr and Cu-Mo PM electrodes produced at three different mixing ratios (15, 25, and 35wt% Cr or Mo), compacting pressures (P-c = 600, 700, and 800MPa), and sintering temperatures (T-s = 800, 850, and 900 degrees C) are compared with those machined with electrolytic Cu and Cu PM electrodes when machining SAE 1040 steel workpiece. Analyses revealed that tool materials were deposited as a layer over the work surface yielding high surface hardness, strong abrasion, and corrosion resistance. Moreover, the mixing ratio, P-c, and T-s affect the MRR, EWR, and R-a values.Article Citation - WoS: 6Citation - Scopus: 6Design and Implementation of an Electrode Feed Rate Control System in the Electrochemical Drilling Process(Springer Heidelberg, 2022) Cogun, Can; Ozerkan, Haci BekirThe interelectrode gap distance control is essential for preventing short circuit and spark discharge occurrences in the machining gap and ensuring a constant distance between the tool electrode (shortly electrode) and the workpiece throughout the electrochemical drilling (ECD) process. In this study, a gap distance control system was designed and implemented in the constructed ECD machine tool. The gap distance control strategy was based on the machining current's discrete measurement (in microsecond intervals) and changing the gap distance according to a set current value by feeding the electrode towards the workpiece or retracting it during the ECD process. The small diameter deep hole ECD experiments were conducted using 0.5 mm diameter side insulated tubular rotational electrodes with through-hole electrolyte flushing to drill Hadfield and AISI 1040 steels. The experimental results demonstrated the success of the developed control system in ECD operations yielding uniform hole geometries and smooth hole surfaces. The use of the control system eliminated the undesirable formations of spark discharges and short circuit pulses.Article Citation - WoS: 7Citation - Scopus: 7Development and Experimental Investigation of Electrochemical Drilling Method Using Rotary Tube Tool(Gazi Univ, Fac Engineering Architecture, 2013) Ozerkan, H. Bekir; Çoğun, Can; Cogun, Can; Mekatronik MühendisliğiIn this study, a new hybrid electrochemical drilling (ECD) method, based on electrochemical machining in nonconventional machining processes, was developed. In the developed method, tube tool makes rotary motion together with inner through hole flushing. A small scale prototype ECD machine has been designed and manufactured to test the developed method. One of the important features of the new system is the regulation of tool feed rate using current feedback control. The Hadfield (manganese) steel, whose strain hardening behavior makes it very difficult to machine with conventional methods, and AISI 1040 steel, whose machinability is fairly good, were drilled using the prototype machine and results were compared. Workpiece material removal rate increased with the increasing machining voltage, tool rotational speed, electrolyte concentration and flushing pressure in both types of steels. Average radial overcut values increased with the rotational speed of the tool. The AISI 1040 steel hole geometries were regular than that of Hadfield steel. Experimental results showed that deep holes can be drilled successfully with the proposed hybrid ECD method.Article Citation - Scopus: 6The Comparison of Performance of Electrolytic Cu and Cube Tool Electrodes in Electric Discharge Machining of Ti6al4v Alloy(TUBITAK, 2021) Bozkurt, F.; Özerkan, H.B.; Çoğun, C.; Uslan, İ.; Urtekin, L.The most crucial cost element of Electric Discharge Machining (EDM) is the production of tool electrode (shortly electrode). Copper, its alloys, and graphite are the most commonly used electrode materials. Selecting the proper electrode material with low production and material cost, high workpiece material removal rate (MRR) and low tool electrode wear rate (TWR) is key to reducing machining costs with EDM. In this study, the EDM performance of CuBe tool electrodes in the machining of Ti6Al4V alloy was experimentally investigated in comparison to electrolytic Cu (E-Cu) electrodes for different pulse time (ts) and discharge current (I) settings. An increase in MRR and a decrease in TWR and relative wear (RW=TWR/MRR) were observed in machining with CuBe electrodes. However, the high raw material cost of CuBe alloy is an essential drawback in widely using these electrodes in industrial applications. A new performance index formulation is introduced for EDM applications that factor in the production cost of the electrode and its life (i.e., RW). According to our results, the CuBe could be used advantageously as the electrode material at medium current settings. However, at low and high current settings, the low raw material cost of E-Cu makes it more favorable. © 2021, TUBITAK. All rights reserved.Article Citation - WoS: 1Citation - Scopus: 1Performance Analysis of Dielectric Application Methods in Electrical Discharge Machining(Sage Publications Ltd, 2025) Cogun, Can; Tosun, NihatA lack of comprehensive research exists on the machining performance of the reciprocating electrode method (REM) compared to other dielectric application methods (DAMs), particularly the commonly used side flushing method (SFM) in electric discharge machining. This study aims to investigate the performance outputs of the two methods under varying machining parameters through experimental and statistical analysis to fill the gap in the field. The impact of each machining parameter and DAM on the critical performance outputs was also determined using the analysis of variance (ANOVA). The study employed signal-to-noise ratio analysis to ascertain the optimal machining parameter settings. It has been demonstrated that the REM has several advantages over the SFM, including a 2-25% reduction in average surface roughness, a 5-70% decrease in electrode wear rate, a smoother workpiece surface, and sharper edges. However, the SFM exhibits a higher workpiece removal rate and less relative wear (RW) than the REM. The ANOVA revealed that the primary factor influencing the RW was the pulse time, followed by the discharge current and the DAM. Similarly, the discharge current was the primary factor affecting the average roughness and mean spacing between successive profile peaks, followed by the pulse time.Conference Object Elektrolitik ve alaşım bakır elektrotların elektro-erozyon ile işleme performansına etkisi(2014) Çoğun, Can; Şimşek, ÜlkeElektro erozyon ile işlemenin (EEİ) en önemli maliyet unsuru elektrotun üretilmesidir. EEİ’de en yaygın kullanılan elektrot malzemeleri bakır ve alaşımlarıdır. Maliyeti arttırmadan EEİ yapmanın yolu, hammadde maliyeti düşük, işlemesi kolay ve elektriksel aşınma direnci yüksek bakır alaşımlarını tespit etmektir. Bu çalışmada, EEİ’de elektrot olarak kullanılan elektrolitik bakır, CuCr1Zr ve CuCo2Be bakır alaşımları için işleme hızı, elektrot aşınma hızı, bağıl aşınma ve işparçası yüzey pürüzlülüğü gibi performans çıktıları deneysel olarak incelenmiştir. Ayrıca, CuCr1Zr alaşımına uygulanan yaşlandırma işlemi sonrası artan elektriksel iletkenliğin EEİ performans çıktılarına etkileri incelenmiştir. Performans çıktılarının alaşım türünden ve uygulanan yaşlandırma işleminden etkilendiği görülmüştür.Article Citation - WoS: 17Citation - Scopus: 18Effects of Electrolytic Copper and Copper Alloy Electrodes on Machining Performance in Electrical Discharge Machining (Edm)(Taylor & Francis inc, 2022) Esen, Ziya; Simsek, Ulke; Cogun, CanThe most important cost element of electric discharge machining (EDM) is the production of tool electrode (shortly electrode). In the EDM process, copper and its alloys are often used as electrode materials. The machining with EDM without increasing the costs can be achieved by selecting the proper electrode with low production and material costs as well as high workpiece material removal rate (MRR), low electrode wear rate (EWR), and relative wear (RW = MRR/EWR). In this study, the EDM performance outputs, namely, MRR and RW were experimentally investigated for electrolytic copper, CuCr1Zr (with and without aging treatment) and CuCo2Be alloy electrode materials for varying machining parameters. The performance outputs were affected by the electrode material and the applied aging treatment. The aged CuCr1Zr alloy electrodes had higher electrical conductivity and better machining performance than the as-received alloy. The CuCo2Be alloy electrodes exhibited moderate to high MRR; however, their RW was the highest. Although the electrolytic copper has moderate MRR performance compared to the investigated alloys, its low cost increased its performance index, making it a more suitable electrode material for EDM applications.