Esen, Ziya

Loading...

Profile URL

Name Variants

Esen, Ziya

Esen, Ziya

Esen, Ziya

Esen, Ziya

Esen, Ziya

Job Title

Prof. Dr.

Email Address

ziyaesen@cankaya.edu.tr

Main Affiliation

09.01. Ortak Dersler Bölümü

09. Rektörlük

01. Çankaya Üniversitesi

09.01. Ortak Dersler Bölümü

Ortak Dersler Bölümü

09. Rektörlük

01. Çankaya Üniversitesi

09. Rektörlük

01. Çankaya Üniversitesi

09.01. Ortak Dersler Bölümü

Ortak Dersler Bölümü

09. Rektörlük

01. Çankaya Üniversitesi

Status

Current Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Files

Sustainable Development Goals

13

CLIMATE ACTION

0

Research Products

8

DECENT WORK AND ECONOMIC GROWTH

0

Research Products

3

GOOD HEALTH AND WELL-BEING

0

Research Products

15

LIFE ON LAND

0

Research Products

17

PARTNERSHIPS FOR THE GOALS

0

Research Products

14

LIFE BELOW WATER

0

Research Products

4

QUALITY EDUCATION

0

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

0

Research Products

6

CLEAN WATER AND SANITATION

0

Research Products

10

REDUCED INEQUALITIES

0

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

9

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

0

Research Products

2

ZERO HUNGER

0

Research Products

1

NO POVERTY

0

Research Products

7

AFFORDABLE AND CLEAN ENERGY

2

Research Products

5

GENDER EQUALITY

0

Research Products

16

PEACE, JUSTICE AND STRONG INSTITUTIONS

0

Research Products

Scopus data could not be loaded because of an error. Please refresh the page or try again later.

This researcher does not have a WoS ID.

Scholarly Output

34

Articles

26

Views / Downloads

1280/46

Supervised MSc Theses

1

Supervised PhD Theses

0

WoS Citation Count

678

Scopus Citation Count

744

WoS h-index

16

Scopus h-index

17

Patents

0

Projects

0

WoS Citations per Publication

19.94

Scopus Citations per Publication

21.88

Open Access Source

3

Supervised Theses

1

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Materials Science and Engineering: A | 4 |

| Journal of the Mechanical Behavior of Biomedical Materials | 2 |

| Journal of Materials Engineering and Performance | 2 |

| Advanced Composites and Hybrid Materials | 1 |

| Advances in Materials and Processing Technologies | 1 |

Current Page: 1 / 6

Scopus Quartile Distribution

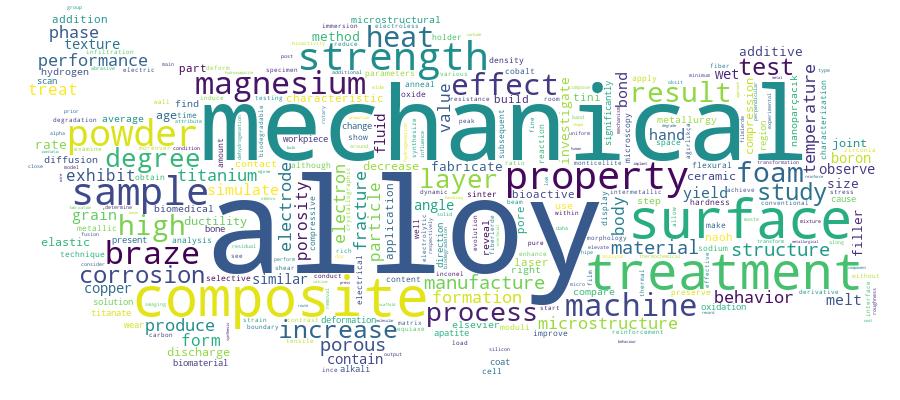

Competency Cloud

34 results

Scholarly Output Search Results

Now showing 1 - 10 of 34

Article Citation - WoS: 1Citation - Scopus: 1Interfacial Behavior and Diffusion Mechanisms of Bni-2 Brazing on Titanium Alloy: Experimental and Molecular Dynamics Insights(Springer, 2025) Goynuk, Tansu; Esen, Ziya; Karakaya, IshakContextJoining titanium alloys, particularly Ti-6Al-4V, is crucial in aerospace applications where reliable, high-performance joints are needed. Brazing offers an effective solution, enabling the joining of dissimilar materials without melting the base metals. However, optimizing the wetting and diffusion behavior of filler metals remains a challenge. This study investigates the high-temperature interaction between BNi-2 filler alloy and Ti-6Al-4V. Boron, the primary melting point depressant in BNi-2, was examined due to its small atomic size and interstitial diffusion mechanism. Elevated temperatures led to improved wetting, reflected by decreased contact angles. Both wetting angles and boron diffusion coefficients were obtained through molecular dynamics simulations and experimental measurements, showing reasonable correlation. These results provide valuable insight into interfacial mechanisms and support further optimization of brazing parameters.MethodsMolecular dynamics simulations were performed using LAMMPS to analyze the temperature-dependent wetting behavior of molten BNi-2 on Ti-6Al-4V and track atomic-scale diffusion. Initial atomic configurations were modeled and simulated under various conditions. Trajectory data were analyzed using OVITO for structural evolution. Boron diffusion was evaluated by calculating mean square displacement from LAMMPS outputs. These values were used to derive diffusion coefficients and activation energies. Parallel experiments were conducted to assess wetting angles and diffusion behavior, and simulation results were compared with experimental data. The consistency between both approaches highlights the reliability of the modeling framework in capturing essential mechanisms during the brazing process.Article Citation - WoS: 25Citation - Scopus: 27Microstructural and Texture Evolution During Thermo-Hydrogen Processing of Ti6al4v Alloys Produced by Electron Beam Melting(Elsevier Science inc, 2020) Esen, Ziya; Davut, Kemal; Tan, Evren; Gumus, Berkay; Dericioglu, Arcan F.; Dogu, Merve NurThe present study was conducted to reveal the effects of building angles and post heat-treatments (2-step Thermo-Hydrogen Processing (THP) and conventional annealing treatment) on the density, microstructure and texture of Ti6Al4V alloy parts produced by Electron Beam Melting (EBM). The results showed that regardless of the building angle; the density, microstructure and crystallographic texture (defined with respect to building angle) of the as-produced samples were identical; having Widmanstatten a structure and columnar beta-grains which are parallel to building direction. The main texture component for the alpha phase was (10 (1) over bar0)//building direction, and for beta phase (001)//building or heat flow direction. The first step of THP, namely, the hydrogenation step, produced a needle-like microstructure and increased the local misorientations due to lattice distortion. On the other hand, after application of the second step of THP, dehydrogenation step, microstructure was refined, particularly alpha-grains that were larger than 10 mu m and located at grain boundaries. Moreover, THP randomized the crystallographic texture since it involves beta to alpha phase transformation, at which one beta-grain can produce 12 distinct alpha-variants. The grain boundary misorientation distributions also changed in accordance with the microstructural changes during the 2-step THP. On the other hand, annealing coarsened the grain boundary and Widmanstatten alpha phases; moreover, it changed the texture so that the basal planes (0001) rotated 30 degrees around the building direction.Article Citation - WoS: 11Citation - Scopus: 11Effect of Sn Alloying on the Diffusion Bonding Behavior of Al-Mg Alloys(Springer, 2017) Esen, Ziya; Dericioglu, Arcan F.; Atabay, Sila EceEffect of Sn as an alloying element on the diffusion-bonding behavior of Al-Mg-Si alloy has been studied by means of differential scanning calorimetry (DSC), X-ray diffraction (XRD), scanning electron microscopy (SEM) and mechanical testing of the diffusion-bonded joint. XRD results revealed the formation of Mg2Sn and (Sn) phases during solidification following induction casting. DSC results showed local liquid (Sn) formation during the bonding process for Sn-containing alloys, where its amount was found to be increasing with the increasing Sn content. Results revealed that Sn addition leads to an increase in the bond shear strength of the diffusion-bonded joints and elimination of the irregularities formed on the bonded interface. Fractured surfaces showed that formation of (Sn) layer at the bonded interface causes the fracture to transform from the ductile to the mixed fracture mode.Article Investigations on the Effect of Secondary Treatments on Ti48Al2Cr2Nb Alloy Manufactured by Electron Beam Powder Bed Fusion Method(Elsevier Sci Ltd, 2025) Bilgin, Guney Mert; Ozer, Seren; Davut, Kemal; Esen, Ziya; Dericioglu, Arcan F.As-built Ti48Al2Cr2Nb alloy samples produced by electron beam powder bed fusion (PBF-EB) exhibited notable brittleness. The low ductility was attributed to coarse gamma bands aligned perpendicular to the building and tensile direction. Additionally, variations in aluminum content and hardness between the coarse colonies and fine gamma/alpha(2) lamellae contribute to this phenomenon. Electron backscattered diffraction (EBSD) studies revealed a higher amount of dislocation density and inherent strain after PBF-EB manufacturing. Hence, usage of Ti48Al2Cr2Nb alloy in the as-built condition in aviation applications with high loads and demanding environments is not found to be viable. To eliminate these negative aspects and make PBF-EB produced Ti48Al2Cr2Nb alloy available for demanding applications, two distinct post-processing heat treatments; namely, hot isostatic pressing (HIP) and annealing heat treatment (HT) were employed at 1200 degrees C. A comprehensive characterization covering microstructure analysis, EBSD, fracture surface examination, as well as room and high-temperature tensile tests allowed determination of the effect of post-processes. HIPing altered the banded structure observed in the as-built samples by increasing the amount of alpha(2) phase and grain size. On the other hand, HT made the banded structure more pronounced without significantly increasing the amount of alpha(2) phase. HT also strengthened the <001> texture, while HIPing introduced randomization of grains. On the other hand, complete recrystallization is achieved as a result of HT at 1200 degrees C for 2 h, whereas HIPing at the same temperature for 2 h induced only 80.5 % recrystallization. In both post-processes, dislocation density and inherent strain were reduced. Room temperature and high-temperature tensile tests demonstrated that both HIPing and HT eliminated the extreme brittleness of the as-built samples.Master Thesis Elektro Eğirme Tekniği ile Elde Edilmiş Tco İnce Filmlerde Nanoparçacık İlavesinin Elektriksel Özelliklere Etkisi(2024) Çelik, Burak; Esen, Ziya; Duygulu, NilüferBu çalışmada elektro eğirme yöntemiyle üretilen ve saydam iletken oksit bir cam olan indiyum kalay oksitin (ITO) yüzeyine kaplananan fiberlerde nano parçacık katkılamanın fiberlerin yapısı ve elde edilen ince film elektrik özelliklerine etkisi araştırılmıştır. Bu amaçla, Polivinil Alkol (PVA) sulu çözeltisi hazırlanmış ve manyetik karıştırma yöntemiyle ağırlıkça % 3, 5, 10 and 20 oranında gümüş, çinko oksit ve titanyum oksit katkılaması yapılmıştır. Daha sonra nanoparçacık takviye edilmiş PVA çözeltileri ITO camın üstüne bir saat süreyle elektro eğirme yöntemiyle kaplanlanmıştır. Elde edilen filmlerdeki nanoparçacık takviyeli fiberlerin yapıları taramalı electron mikroskobu ile incelenmiş ve elde edilen ince fimlerin direnç ve özdirençleri değerleri belirlenmiştir. PVA fiberlerin içinde bulunan nano parçacıkların topaklandığı ve topaklanan bölgelerin büyüklüğünün kullanılan çözelti içindeki nanoparçacık miktarının artmasıyla birlikte arttığı görülmüştür. En az topaklanma TiO2 takviyeli fiberlerde görülmüş olup, en düşük topaklanma büyüklüğü olan 643.7 ± 85.5 nm ağırlıkça %3 TiO2 eklenen fiberlerde tespit edilmiştir. Benzer şekilde, en küçük fiber çapı ve homojen fiber büyüklük dağılımı TiO2 katkılı fiberlerde görülmüştür. Örneğin, ağırlıkça %3 TiO2, ZnO ve Ag nanoparçacık içeren fiberlerde fiber çapları sırasıyla 370, 376 and 380 nm olarak ölçülmüştür. TiO2 katkılı fiberlerdeki daha az topaklanma ve homojen fiber büyüklük dağılımı ITO cam üzerinde oluşturulan ince filmin elektriksel iletkenliğini de olumlu yönde etkilemiştir. Farklı miktarda nanoparçacık içeren tüm filmlerde nanoparçacık miktarının düşüşüyle birlikte film direnç ve özdirenci de düşmüştür. TiO2 içeren ince filmlerde, film direnci ITO camın direncine (34 ohm) nanoparçacık takviyesi ağırlıkça %10'a düşürüldüğünde ulaşmıştır ve daha az miktarda TiO2 ince filmler hedeflendiği şekilde ITO cama göre daha düşük direnç sergilemişlerdir. Diğer yandan, ZnO ve Ag takviyeli ince filmlerde ITO cam direncine ancak nanoparçacık miktarı ağırlıkça %5'e düşürüldüğünde ulaşılabilmiştir.Article Citation - WoS: 32Citation - Scopus: 36Optimization of the Mechanical Properties of Ti-6al Alloy Fabricated by Selective Laser Melting Using Thermohydrogen Processes(Elsevier Science Sa, 2017) Esen, Ziya; Akin, Seniz Kushan; Dericioglu, Arcan F.; Bilgin, Guney Mert2-step Thermo Hydrogen Process (THP) including hydrogenation and dehydrogenation steps was applied to Ti-6Al-4V alloy fabricated by selective laser melting (SLM) process to refine the microstructure and to increase the ductility of the alloy. It was observed that as-fabricated alloy's surface was composed of oxides of titanium and aluminum, which may alter the hydrogenation kinetics. The hydrogen treatment for 1 hat 650 degrees C, the maximum hydrogen solubility temperature of the alloy, transformed starting non-equilibrium alpha'-martensitic phase to 13 and 8 (TiH2) phases. On the other hand, very fine discontinuous beta-phase was formed along with alpha-phase as a result of dehydrogenation at 700 degrees C for 18 h, which decreased the hydrogen level well below the starting value and caused transformation of delta-phase to fine alpha-phase. In contrast to commonly used THP treatments consisting of betatizing at high temperature, 2-step treatment prevented grain boundary alpha-phase formation as well as excessive grain growth. About 110% and 240% increments were detected in % Elongation (EL) and % Reduction in Area (RA) values, respectively, as a result of 2-step THP, while the strength decrease was limited to 10%. The change in ductility of the alloy was also verified by transformation of flat and shiny fracture surfaces seen in SLM fabricated alloy to a fracture surface containing equiaxed dimples after THP treatment. The hardness drop in the alloy after hydrogenation and dehydrogenation treatments was attributed to relief of residual stress and formation of equilibrium alpha and beta-phases.Article Citation - Scopus: 41Characterization of Loose Powder Sintered Porous Titanium and Ti6al4v Alloy(2009) Bor, Şakir; Esen, Ziya; Bor, Elif TarhanPorous titanium and Ti6Al4V alloy, biomedical candidate materials for use in orthopedic and dental implants, were manufactured by sintering the powders at various temperatures in loose condition. The characteristics of the corresponding powders and utilized sintering temperatures limited the final porosities in the range 30-37.5 vol. %. Similar to wrought alloys, compression stress-strain curves of porous samples exhibited 3 distinct deformation regions containing an elastic region, subsequent to yielding strain hardening region up to a peak stress and fast fracture after small straining. The mechanical properties of porous samples of both types were observed to obey minimum solid area (MSA) models in which the bond regions between particles perpendicular to loading direction are assumed to dominate in transmission of stress. A linear relation was obtained between yield strength and square of neck size ratio, (X/D)2, where X and D represent the average neck and particle diameters, respectively.Article Citation - WoS: 102Citation - Scopus: 119Characterization of Ti-6al Alloy Foams Synthesized by Space Holder Technique(Elsevier Science Sa, 2011) Bor, Sakir; Esen, ZiyaTi-6Al-4V foams, biomedical candidate materials, were synthesized by powder metallurgical space holder technique as a result of evaporation of magnesium to achieve desired porosity content. Final products contained porosities in the range similar to 43-64% with an average macropore size between 485 and 572 mu m and a lamellar type Widmanstatten microstructure composed of alpha-platelets and beta-laths. Unlike the case of bulk Ti-6Al-4V alloy tested under compression loading, compression stress-strain curves of manufactured Ti-6Al-4V foams were similar to those of elastic-plastic foams, which contain a linear elastic region; a plateau stage: and a densification stage. In the plateau region deformation bands perpendicular to the compression axis were developed and cell collapsing took place together with the buckling and fracture of some of the cell walls and edges in a ductile manner. Calculated elastic modulus and yield strength were in the range 1.42-14.7 GPa and 28.2-150 MPa, respectively, and the foam mechanical properties were found to be dependent on micro porous cell wall properties, which in turn depends on neck size between powder particles. Around 330 MPa yield strength value was calculated for porous cell walls by the use of Ti-6Al-4V alloy powder samples sintered in loose and compacted conditions, which were utilized to simulate the cell wall structure of foams. In addition, overall mechanical properties of foam s were investigated considering macro porosity fraction, p(macro), and the yield strength of foams exhibited a power law dependence, similar to commonly used minimum solid area models, in the form of A*(1 - p(marco))(n), where the proportionality constant "A" was found to be the yield strength of micro porous cell walls. (C) 2011 Elsevier B.V. All rights reserved.Book Part Citation - WoS: 36Corrosion of Metallic Biomaterials(Springer-verlag Berlin, 2015) Esen, Ziya; Duygulu, Ozgur; Gungor, Serap; Dikici, BurakMetallic materials have been used as biomedical implants for various parts of the human body for many decades. The physiological environment (body fluid) is considered to be extremely corrosive to metallic surfaces; and corrosion is one of the major problems to the widespread use of the metals in the human body since the corrosion products can cause infections, local pain, swelling, and loosening of the implants. Recently, the most common corrosion-resistant metallic biomaterials are made of stainless steels and titanium and its alloys along with cobalt chromium molybdenum alloys. It is well known that protective surface films of the alloys play a key role in corrosion of the metallic implants. Key documents on the corrosion behavior of the metallic biomaterials in human body have been compiled under this chapter as a review.Article Citation - WoS: 62Citation - Scopus: 69Titanium-Magnesium Based Composites: Mechanical Properties and In-Vitro Corrosion Response in Ringer's Solution(Elsevier Science Sa, 2013) Esen, Ziya; Dikici, Burak; Duygulu, Ozgur; Dericioglu, Arcan F.Ti-Mg composite rods exhibiting both bioinert and biodegradable characteristics have been manufactured by hot rotary swaging from elemental powders of titanium and magnesium. As a result of processing, spherical magnesium powders elongated in the direction of deformation and the dendritic structure in starting magnesium powders transformed into highly equiaxed grains. Magnesium particles in the outer layer of the composites were decorated by thin layer of MgO while the interior parts were free from oxides. As expected, Young's moduli, yield and peak strengths of the composites were observed to decrease with an increase in the magnesium content, while ductility of composites was enhanced by decreasing the amount of titanium. Composites fractured at an angle 45 to the loading axis along the titanium particle boundaries and through the magnesium particles via transgranular type of fracture with the accumulation of twins near the fracture surface of magnesium. Mechanical properties of the composites were observed to be comparable to that of bone and the composites exhibited biodegradable and bioinert character upon testing in Ringer's solution such that magnesium was selectively corroded and pores were formed at prior magnesium powder sites while titanium preserved its starting skeleton structure. In addition, it was found that volume ratio of titanium and magnesium, and continuous MgO layer are the most important parameters which should be considered in designing biodegradable magnesium alloys with an appropriate corrosion rate. (C) 2013 Elsevier B.V. All rights reserved.